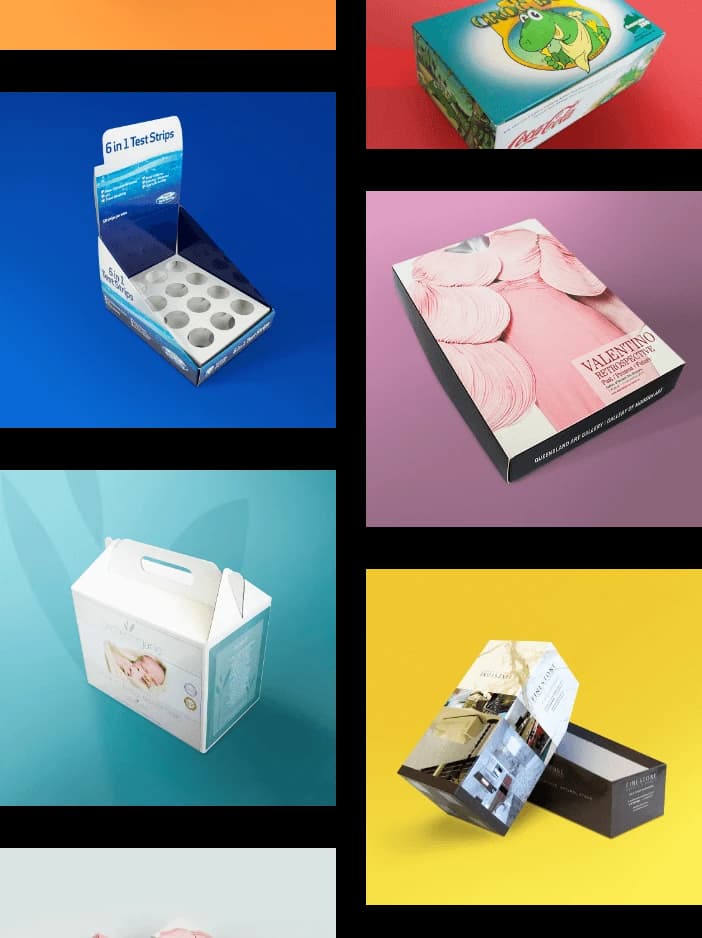

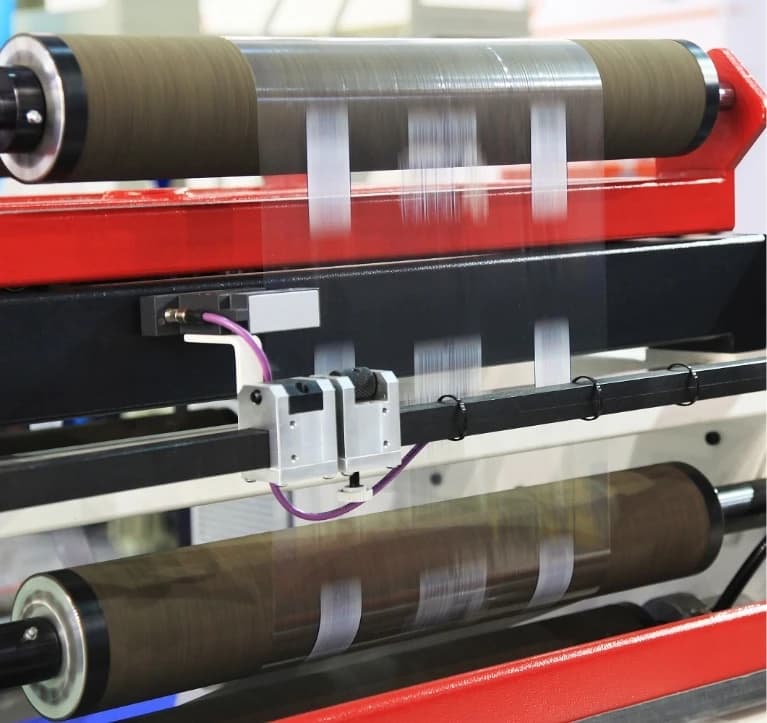

Offset Printing

A traditional printing method using large printing presses. This form of printing involves transferring an image from a metal plate to a rubber blanket and then onto the printing surface. The metal plate is etched with the desired image or text, and then ink is applied to the plate.

Suitable For:

Large runs, and it’s an efficient and cost-effective option for printing high-quality images and text.